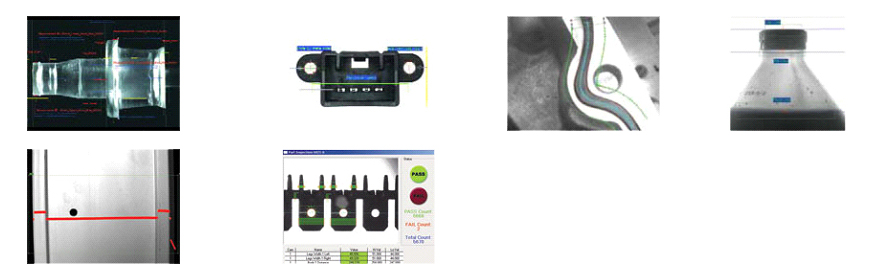

Measuring, Gauging, and Verifying Tolerances

Manufacturing requirements for measurement range from presence verification to checking high-precision dimensional accuracy and geometrical tolerances. Attention to the inspection environment and image quality is as important as the vision algorithms themselves. DALSA sub-pixel measurement tools, combined with the right optics and stable lighting, provide the precision and repeatability to ensure manufacturing accuracy.

Measurement Applications

Teledyne DALSA Machine Vision Capabilities and Tools

• High speed, low light, high resolution image capture

• position (search) tools to accurately landmark measurements on moving parts

• Calibration tools to remove camera misrepresentation and translate sub-pixel measurements locally or globally into real world units

• Preprocessing tools to manipulate or improve the camera image to highlight features to measure

• Edge finding tools to accurately find edge transition on parts for gauging

• Shape finding tools to locate distinct shapes like corners on parts

• Geometric fitting tools to fit lines, angles, arcs, and circles to edge points

• Math tools to create custom measurements that span multiple cameras

• Laser tools for measuring height on parts determined by angle of projected laser lines

• Bead tool to measure thickness and uniformity of adhesive beads or similar applications

• Color tools for verifying the amount and location of colored elements.

Get the price immediately (currently in stock) click Here....